| Processing materials | Chipbreakers | Introduction | Vc | Fn | Ap |

|---|---|---|---|---|---|

| Stainless steel |

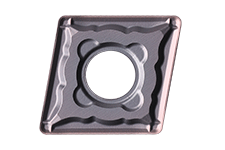

SF | SF Chipbreaker, with sharp cutting edge, matching R0.4 arc angle to achieve high surface finishing. it is suitable for finishing machining of stainless steel continuous cutting. | 130(60-200) | 0.1(0.05-0.3) | 0.5(0.1-0.8) |

MF | MF chipbreaker, ensures sharpness and increased Strengthens of the cutting edges. With high versatility ,it is suitable for continuous machining of stainless steel. | 130(60-200) | 0.1(0.05-0.3) | 1.0(0.2-2.0) | |

FM | FM chipbreaker, enhances strengthens of cutting edges based on MF chipbreaker. With high versatility ,it is suitable for general machining of stainless steel. | 130(110-200) | 0.1(0.05-0.3) | 1.5(0.2-2.0) | |

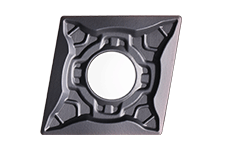

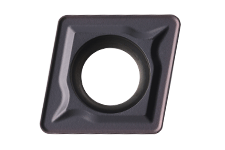

MM | MM chipbreaker, enhances the strengthens of cutting edges. It is suitable for stainless steel intermittent cutting. | 130(110-200) | 0.1(0.05-0.3) | 1.5(0.2-2.0) | |

TT | TT Chipbreaker,ensures sharpness and increased strengthens of the cutting edges.It is the general choice for stainless steel internal hole machining. | 130(80-200) | 0.1(0.05-0.3) | 1.0(0.1-2.0) | |

| Steel |

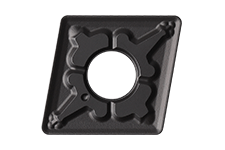

PMF | PMF chipbreaker, with small cutting force and high surface finishing, it is the idea chipbreaker for finishing and semi-finishing machining of steel. | 200(160-320) | 0.2(0.05-0.4) | 1.0(0.1-1.5) |

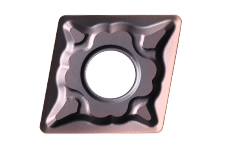

WM | WM chipbreaker, With higher strength than PMF chipbreaker, wider chip breaking range,and strong versatility, it is suitable for steel machining. | 200(160-320) | 0.2(0.05-0.4) | 1.5(0.1-3.0) | |

GR | GR chipbreaker, with high cutting edge strength,it is the first choice for light-load roughing machining of steel. | 180(160-320) | 0.2(0.05-0.4) | 2.0(1.0-4.0) | |

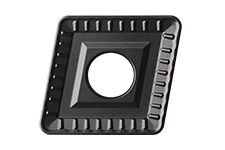

GTR | GTR chipbreaker,single-sided, with strong cutting edges, it is the first choice for heavy-load roughing machining of steel. | 180(160-320) | 0.2(0.05-0.4) | 3.0(2.0-5.0) | |

TM | TM chipbreaker,with small cutting force and high strength cutting edges,it is suitable for internal hole machining of steel. | 200(160-320) | 0.2(0.05-0.4) | 1.5(0.1-3.0) | |

HM | HM chipbreaker,with high strength cutting edges,it is suitable for internal hole machining of steel and cast iron. | 200(160-320) | 0.2(0.05-0.4) | 1.5(0.1-3.0) | |

| Cast iron |

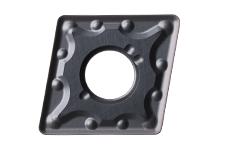

TC | TC chipbreaker,with high strength cutting edges and high versatility, it is suitable for machining of steel and cast iron. | 200(160-320) | 0.2(0.05-0.4) | 1.5(0.1-3.0) |

| The high strength of the cutting edge is a good way to overcome the bad processing factors such as sand eye and slag in cast iron processing, and the general chipbraeker for cast iron processing. | 200(160-320) | 0.2(0.05-0.4) | 1.5(0.1-4.0) |

-

-

Phone+86-13827804388

-

Office Hours Mon - Sat : 8:30 - 5:30(UTC +8:00)