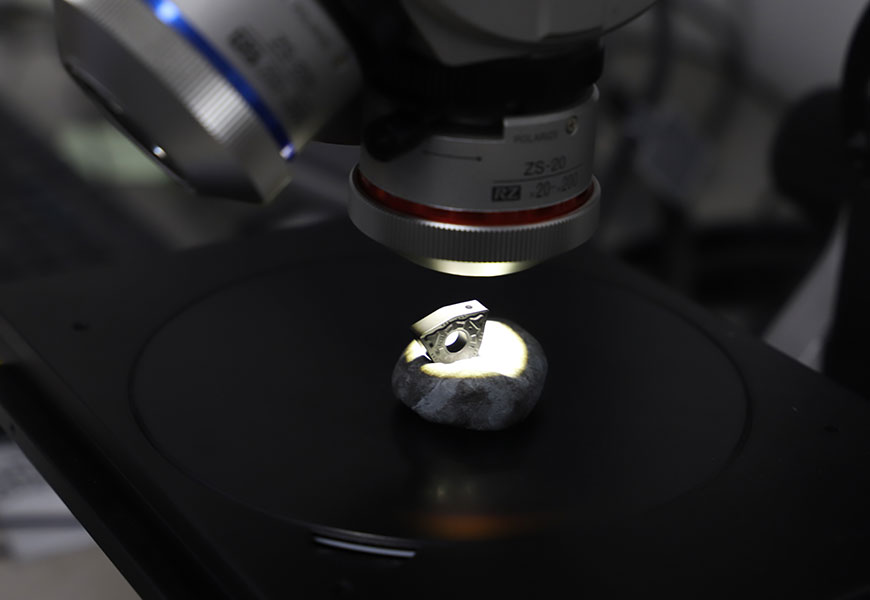

Carbide inserts are often coated with various materials to enhance their performance, extend tool life, and improve resistance to wear and heat. Here are some common coating types applied to carbide inserts:

Titanium Nitride (TiN):

TiN is a widely used coating for carbide inserts. It provides good wear resistance and improves the hardness of the insert. TiN coatings are suitable for general-purpose machining of a variety of materials.

Titanium Carbonitride (TiCN):

TiCN coatings offer increased hardness and wear resistance compared to TiN. They are especially effective in high-speed machining applications and can withstand higher temperatures.

Aluminum Oxide (Al2O3):

Aluminum oxide coatings provide excellent thermal and chemical stability. They are suitable for cutting ferrous materials and high-temperature machining conditions.

Titanium Aluminum Nitride (TiAlN):

TiAlN coatings offer improved hardness, heat resistance, and oxidation resistance. These coatings are suitable for high-speed machining and can handle elevated temperatures.

CVD (Chemical Vapor Deposition) Coatings:

CVD coatings involve depositing thin layers of material onto the carbide insert through a chemical vapor process. Common CVD coatings include titanium carbide (TiC) and aluminum oxide.

PVD (Physical Vapor Deposition) Coatings:

PVD coatings involve the deposition of thin films through a physical process, such as sputtering. Various PVD coatings, including TiN, TiCN, and others, are commonly used on carbide inserts.

The choice of coating depends on the specific machining application, the type of material being cut, and the desired balance of properties such as hardness, wear resistance, and thermal stability. Different coatings excel in different conditions, and selecting the right one can significantly impact the overall performance of the carbide insert.

Related search keywords:

carbide inserts coating, pvd coating carbide inserts, coating for carbide inserts, carbide, pvd coating, CVD coating, carbide inserts, carbide burr, carbide bit, carbide burr bits, carbide blade, carbide cutting tools, carbide cutters